ABC Business Consulting

March 2021

New legislation in Europe from July 2021

How International Standards for electric motor systems support policies of countries using these in their regulations?

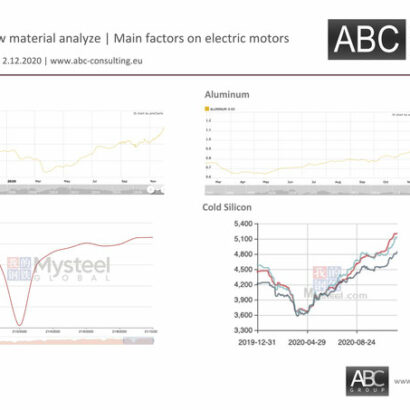

According to the IEA1 electric motor driven systems are responsible for 53% of global electricity use. The IEC has contributed to the definition of energy-efficient electric motor systems through the internationally relevant test standard IEC 60034-2-1 for electric motors and the IEC 60034-30-1 classification scheme comprising four levels of motor efficiency (“IE-code”):

- IE1 Standard Efficiency

- IE2 High Efficiency

- IE3 Premium Efficency

- IE4 Super Premium Efficiency

These IE-codes serve as a reference for governments who specify the efficiency levels for their minimum energy performance standards (MEPS).

Markets:

The European Union has first set motor MEPS in 2009 and has after 10 years upgraded its minimum requirements in 2019 with regulation number 2019/1781 covering a larger scope: electric motors from 0.12 kW to 1000 kW output power including 2-, 4-, 6- and 8-pole motors. From 1 July 2021 motors between 0.75 kW and 1000 kW will be required to meet a minimum efficiency class of IE3, the group of smaller motors from 0.12 kW to 0.75 kW minimum IE2. From 1 July 2023, motors between 75 kW and 200 kW will be required to meet the even higher efficiency class of IE4.

The USA was the first country in the world to set MEPS for motors. In 1997 (Energy Policy Act) the minimum required level was set at the equivalent of IE2. In 2007 (Energy Independence and Security Act) the MEPS were raised to the equivalent of the IE3 level (NEMA Premium), in 2015 the scope was further widened to include small polyphase motors from 0.18 kW up to 2.2 kW with IE3 and single-phase with IE2. The USA currently recognizes in its legal requirements the national testing standard IEEE 112B, the Canadian test standard CSA390 but not yet the IEC test Standard IEC 60034-2-1 (the differences are minimal). The adjustment of the requirements to allow testing according to the IEC standard is under consideration.

Australia and New Zealand set MEPS levels for 0.75 kW to 185 kW at IE2 in 2000 (AS/NZS 1359.5-2000), effective since 2001, based since 2018 on the IEC test standard IEC 60034-2-1.

China has upgraded in 2019 its motor efficiency standard GB 18613 for small and medium three-phase asynchronous motors for 0.12 – 1000 kW and 2-, 4-, 6- and 8-poles aligned with IEC standards. It still has kept its motor MEPS from 0.75 kW to 375 kW at the IE2 level with the date of the formal enforcement of the more advanced MEPS with IE3 and IE4 as a reach standard pending.

Japan decided to align its national JIS with IEC efficiency classes and to include electric motors at the IE2 and IE3 level in its Toprunner programme in 2014.

India has a comparative efficiency label since 2009 and a voluntary standard on IE2 level since 2012.

In 2020, the point was reached where countries consuming 76% of the global electricity consumption by electric motor systems have set MEPS for motors at either IE2 or IE3 level. This is a high level of international alignment for a globally traded product, recognizing at the same time that MEPS can differ according to the market situation of individual countries or regions. The barriers to trade are reduced through the transparent nomenclature and definitions of the IE-code (MEPS levels at IE2 / IE3 / IE4).